A great thing about college sports is that each shirt or decal that someone buys will have a personal meaning behind it. That's what I love the most about college athletics; I feel that fans are more loyal to their favorite school or university because they associate that school or university with some great memories outside of the athletics. I love the NFL but I don't associate as many positive memories with NFL games as I do with college football or basketball games (maybe that's because I'm also a Lions fan, but still).

Not to sound sappy, but in a way, in addition to selling t-shirts and decals, we are selling memories and inter-generational connections. Alumni, current students, prospective students, and families of alumni all can connect over a specific university and the merchandise that goes comes with it (and we are thrilled that you picked us to help you do that).

Working for Nudge is fun because we are in the same merchandising arena as the huge players like Nike and Adidas, but we also are able to offer a little more of a customized experience (reminder - if you want any decals or apparel customized, we can hook you up!). We sold close to 2,000 pieces of apparel (shirts and hoodies) last quarter and what separates us from the huge companies is that every single one of our garments is printed by hand.

I've carried on at length about why our garments are so comfortable, how they compare to a cheaper 100% cotton shirt, and how we go about getting licensed to print shirts, but what is the actual process of how a shirt gets printed?

That's a mighty fine question there reader and it was one that I questioned a lot myself before I joined Nudge and started working in the merchandise and apparel industry.

As mentioned in the licensing blog, we submit individual designs for approval as opposed to just applying for a blanket license from the university, so once a design is approved, we head back to the drawing board!

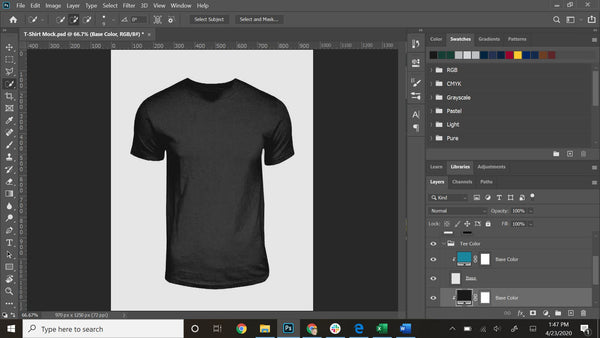

1. Contrary to the popular saying, back to the drawing board is good news for us, because it means it's time to get the printing process starting. We use a combination of Adobe Illustrator and Adobe Photoshop to finalize our designs - below is my 'drawing board', so to speak. I have a .PSD file template that is very easy to use; I simply adjust the colors accordingly and slap on the logos and designs I want and off it goes for approval.

2. At this point, we send the order to Fabricated Customs, our sister company that prints all of our apparel orders. Once approved, we create a film (not a movie!) for every color in the design, a thin and transparent piece material that will be used for alignment and proper execution. We have a special printer that reads the file and prints our design's colors onto the specific material we use.

3. From there, we use the films to make a screen, also one for each color. Screens are made in a dark room on something that looks like a picture frame, about 18 inches wide by 24 inches tall, to mirror the size of the torso of the t-shirt. A screen has an area of mesh that matches the design (and which specific color it is) that allows for the ink to flow through it properly when it comes time to print.

If the design is one that will be printed frequently, the screen is washed of ink and saved for later, but if it is a one-time print or a special run of shirts, it is powerwashed and the film is removed so the screen frame can be recycled and reused for a new design down the road.

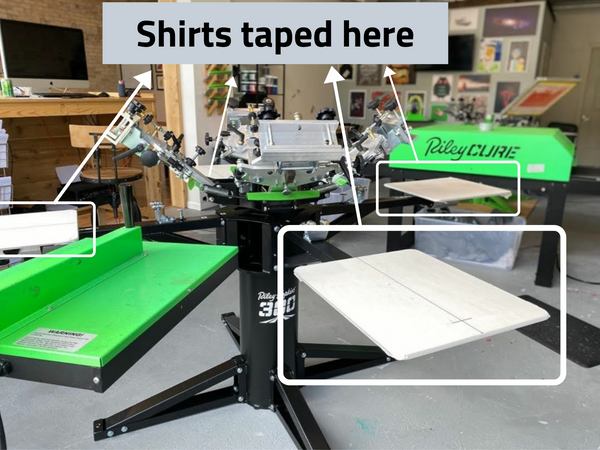

4. After the screens are made, they are attached to the printer.

Unfortunately I don't have a photo of a screen on the printer (and can't get one because I'm not allowed to go to work), so I hope this helps! After the screens are applied, it's time lay the shirt on the press.

The shirts are taped with a special t-shirt tape and aligned using the marks on the board and the screens we mentioned earlier. Once everything is aligned and ready, ink is selected and prepped.

5. Ink! This is Fabricated's ink area; they have tons of different colors and mixes to create colors and match inks to every university and more specifically, each design we have available for those universities. Not all navy blues are the same!

This is Fabricated's ink area; they have tons of different colors and mixes to create colors and match inks to every university and more specifically, each design we have available for those universities. Not all navy blues are the same!

Remember when I said the screen is like a picture frame? The raised edges act like a reservoir to which the ink is applied and therefore it won't splash around.

Above is a photo of a screen applied with ink. Ink is applied (carefully) to the bottom of the screen, much like a painter or artist with their palette of colors. With the screen attached, the t-shirt taped, and the ink applied, it's finally time to print. On the printer, the center pillar acts as an axle in multiple directions, so whoever is printing brings the screen down and either pushes or pulls the ink across the screen so it goes perfectly through the mesh section and only on to the shirt. Then, the printer lifts the screen off of the shirt, rotates the screens around, and brings the next screen down to print the next color.

In the photo above, Fabricated's printer, Jon, is set to push white ink over a Michigan State Spartan helmet design. He starts with a green shirt, attaches the screen that has mesh in the shape of the Spartan helmet, brings the printer down, and pushes the ink across the screen so when he lifts the printer back up, the ink is applied in the shape of the design!

It's an amazingly quick system when the printer gets into a rhythm. A screen-printer can knock out a run of 30 shirts in an hour or so depending on the color and intricacy of the design. Pull down, push ink, lift up, rotate, repeat.

6. Dry. After the ink is applied with every necessary color, it goes into our industrial dryer that will pull any moisture out of the shirt without taking away any integrity of the design. If you've ever been to Quizno's or Potbelly or another toasty sub shop, imagine a similar machine to the one in which they put your sandwich after adding the meat and cheese to it. Similar to a treadmill, there is a belt that runs the shirts under the heat and will simply drop the finished shirt into a bin, where it will picked up for final steps. Unfortunately I don't have photos of the dryer, but click this link to watch a video of how the ink is pressed and the shirt goes into the dryer.

7. Packaging. After it is dried and dropped into the bin, each shirt is bagged, tagged with the appropriate bar code and licensing label, and sorted into the appropriate container, so when you buy it, all we need to do is print a shipping label and get it on the way!

If at any point in the screen-printing process a shirt is ruined (ink goes somewhere it shouldn't, a color is mismatched, a design is aligned improperly), we take it off the press immediately and use it for a test shirt later. We don't want to throw it away because that's extremely wasteful, and not to brag, a lot of my own wardrobe is comprised of shirts with misaligned designs. We're never going to send you a shirt that has any imperfections on it because you're not paying money for a low quality design, material, or print job. And if for some reason it does get shipped to you with an error, we'll send you a new one every single time. It's the best part about working with our own print shop - quality control begins and ends with us. And we're slightly better than Creed Bratton when it comes to quality assurance.

We have an internal stocking system to keep track of how many shirts we have on hand at any given time, so if a certain product starts flying off the shelves, we send an order to Fabricated Customs for them to print another set of that shirt. They knock it out in a day or two and our inventory is replenished - we have it down to a science by now!

Have any other questions about our process? Ask away in the comments or send us an email!

Leave a comment